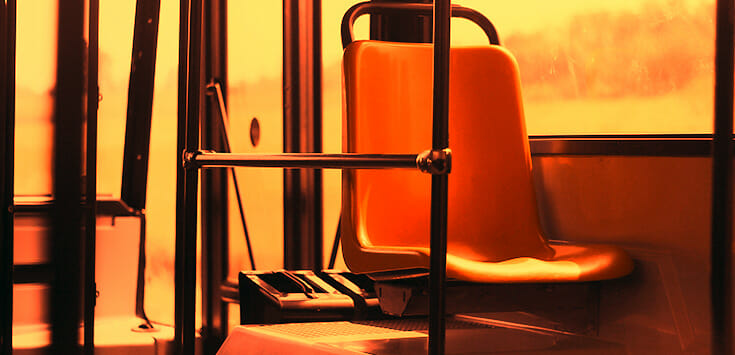

A shuttle bus, (hereinafter referred to as the Bus) that was left in a workshop for floorboard replacement, suddenly caught on fire. The owner, Mr Fin had just gone for lunch with the mechanics, when he received a call from the neighbour, a workshop as well, alerting him that Mr Fin’s “workshop” was on fire. Mr Fin rushed back immediately and saw the Bus on fire and the Fire and Rescue Department (FRD) fighting the fire. The AGI Investigation Team inspected the premises seven (7) months after incident, to investigate the origin and the cause of fire. During the on-site examination, the Team found that the Bus sustained total fire damage where all the combustible materials within the bus were consumed by the fire, leaving only the metal-based components and parts.

A comparison between the nearside and offside of the Bus revealed that the offside sustained more severe fire damage. At the nearside, traces of the wordings on the body were still visible and remains of the paint layer were also still visible at the lower section of the door panels for the luggage compartment. Most of the aluminium strips located above the door panels for the luggage compartment and below the windows were still intact or partially melted.

At the offside of the Bus, the aluminium strip located along the bottom section of the window was mostly intact (refer to red arrows in Photograph 3) except the area above the battery and fuel tank compartments (refer to green arrow in Photograph 3).

A U-pattern was observed on the exterior surface of the door panel for the battery compartment, which indicates high heat intensity within the battery compartment. The aluminium strip above the door panel had melted at the middle section (refer to red arrow in Photograph 4) and remains of aluminium strip was still visible at both ends (refer to blue arrows in Photograph 4).

The area of origin was narrowed down to the battery compartment of the Bus. Examination of the battery compartment of the Bus revealed severe fire damage to the batteries. The exterior plastic casing of the batteries had melted and the interior of the batteries sustained uniform fire damage; hence, ruling out internal failure of the batteries as cause of the fire.

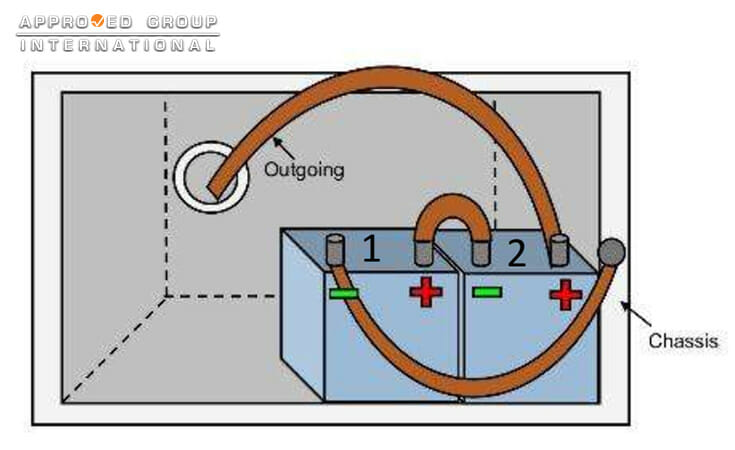

The Team excavated the battery compartment of the Bus and found the interconnecting cable between the two (2) batteries in the battery compartment. The arrangement of the batteries and battery connectors within the battery compartment of the Bus is as follows.

The Bus had two (2) batteries; the negative terminal of the first (left if view from front) battery was connected to the chassis body while the positive terminal was connected to the negative terminal of the second (right if view from the front) battery through an interconnecting cable, and the positive terminal of the second battery was the output that was routed throughout the entire bus. Examination of the interconnecting cable revealed that it sustained severe fire damage. The positive connectors sustained more severe damage and melting as compared to the negative connector (refer to red arrow of Photograph 6).

The interior circumference of the positive connector was unevenly melted and damaged, which indicates that the positive connector was subjected to extremely high intensity of heat, causing the alloy of the connector to melt. This suggests that an electrical overheating had occurred. The investigation later reveal that the Bus was sent for repairs to another workshop prior to the floorboard replacement. The previous repair involved the removal of the battery terminals as a safety measure.

The investigation concluded that the origin of the fire was from the battery of the Bus.

The cause of the fire was due to the improperly tightened battery connectors after the repair work were conducted, which then caused resistance heating and overheating at the positive connector of the interconnecting cable.

The fire initiated from the battery compartment, propagated through the available fuel load via direct flame impingement and heat transfer and affected the entire Bus.