The Back Story

Approved Group International (AGI) was called out to a site visit involving an incident with a Cochran Boiler, that had happened in the previous months. AGI carried out a meticulous survey on the boiler, along with Dr. Boiler’s 3 step framework and a detailed interview with those personnel directly involved and present at the time of the incident.

But First, How Does a Cochran Boiler work?

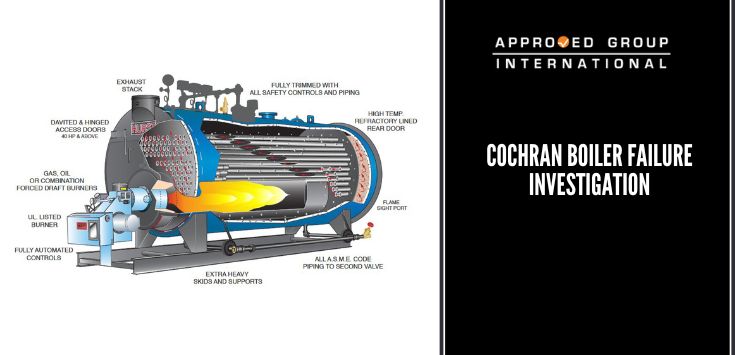

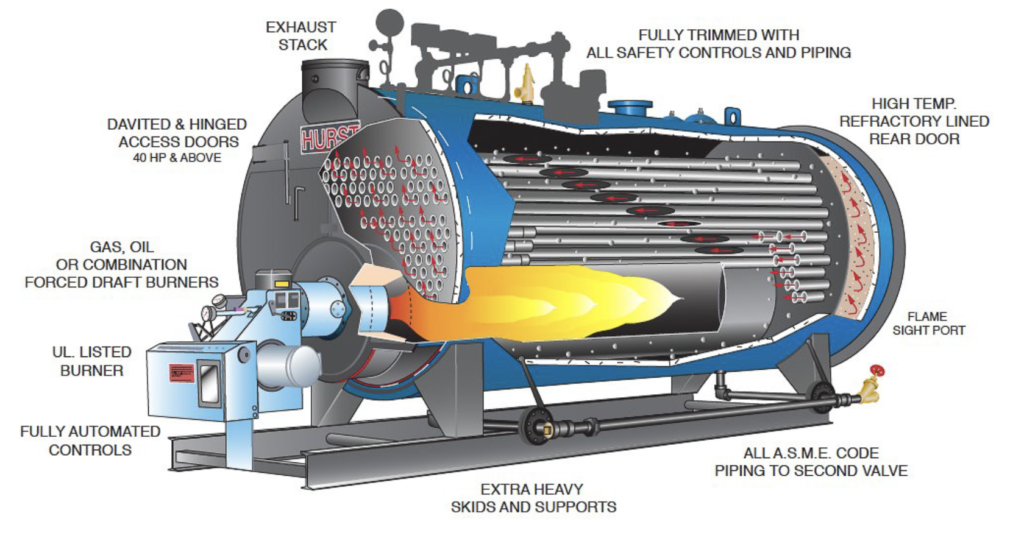

This specific type of Cochran Boiler is a fire/smoke tube boiler. Fuel is introduced into the burner which is positioned horizontally at the furnace located at the bottom of the boiler. The burner atomizes the fuel through nozzles at the tip of the burner and the atomized fuel is lit up by electrodes placed in the line of atomization. The atomized flame is propagated horizontally in the furnace. The propagation of the flame and the air required for the combustion is supplied by the inbuilt forced draft fan attached to the burner.

Initial heat exchange occurs through the walls of the furnace which is submerged in the feed water. The radiation from the flame produced by the burner transmits thermal energy through the furnace wall to the feed water; initial feed water heating is achieved here.

The flue gasses from the combustion travels out of the furnace and enters the fire/smoke tubes of the boiler. Similar to the furnace, the external circumferential surface of the smoke/fire tubes are submerged in the feed water. Flue gasses passing through the internal section of the smoke/fire tubes, transmits thermal energy through convection and conduction to the feed water. This process further heats up the feed water and produces steam. Finally, the flue gasses exit the smoke/fire tube and are sent out to the atmosphere through the exhaust stack.

The produced steam is supplied to its consumers through a steam stop valve located at the top of the boiler. For safe operations of the boiler, boiler mountings, such as gauge glass, safety valve, scum and bottom blowdown valve, feed check valve, pressure gauge, and vent valve are available on the boiler. To add, advance safety is achieved by visual and audible alarms that activate when the boiler water level is too high or too low, when steam pressure is above its rated capacity and when the flame during start-up is not achieved. These alarms work with the help of water level transmitters, pressure transducers and flame sensors.

AGI Case Study Damage Assessment Process

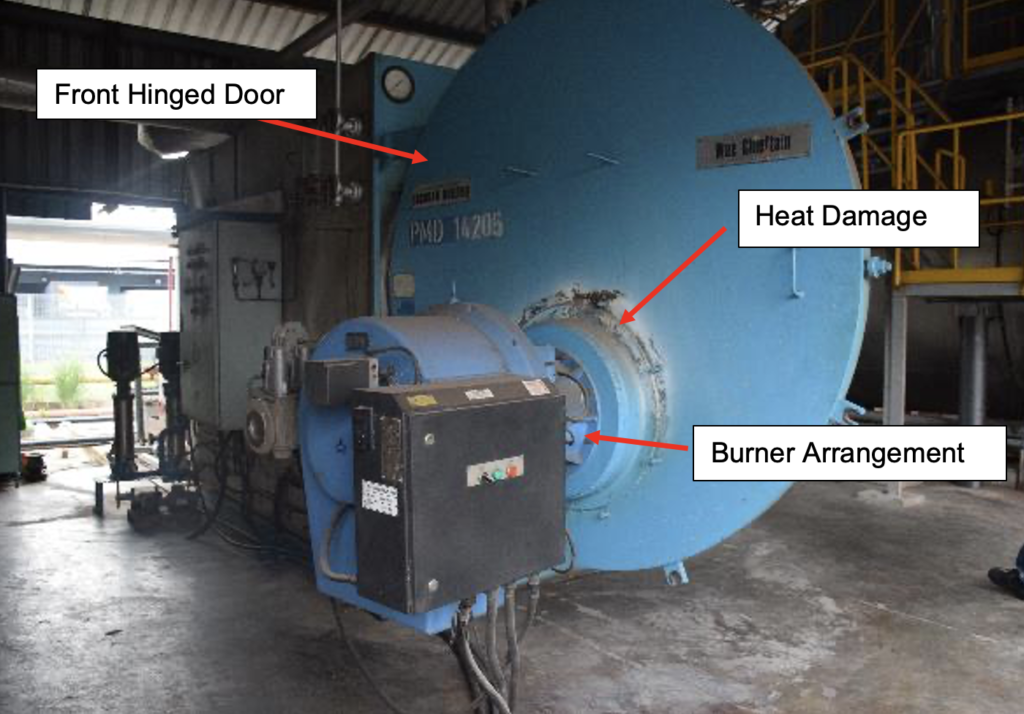

Arriving onsite, AGI observed the cordoned off area surrounding the Cochran Boiler and with help from the maintenance team, began an internal inspection opening the front and rear ends. All our inspections carried out were documented through a sequence of photography, video recordings, and a 3D scan.

The testing process follows a rigorous procedure including the interviewing of relevant and directly involved personnel.

AGI Case Study Examination Findings

Heat damage was found on the front exterior

Severe heat damage to the interior furnace wall causing a ‘clove’ like formation

with a thin layer of brittle carbon apparent

Picture 3: ‘Clove’ like formation

Extensive crumbling of the refractory

Dismantled natural gas line to the burner fuel inlet

Signs of oxidation in the upper section, forming a 180-degree circle displayed from the rear end of the boiler

Tubes appeared to have bent and oxidation was noticed on the internal surface of the tubes, showed observations made from the rear end

Signs of deformation of the boiler exterior exhibited from the rear view of the left side

What Forensically can be ‘Ruled out” or ‘Ruled in’ when a Cochran Boiler Fails?

Possible Failure – Unburnt Fuel – ‘Ruled out.’

Cause

Poor burner maintenance

Poor air supply

Repetitive misfiring of boiler neglect and firing up again without purging the boiler first.

There was no evidence present to prove this possible cause of failure.

Possible Failure

Improper boiler water properties – ‘Ruled out.’

Cause

Scale

Sludge

Corrosion

Impurities Cary Over

In this case study there was no visible evidence to correlate any of the above.

Possible Failure

Non-Compliance to Standard Operating Procedures – Contributing factor

Cause

Competent personnel must handle pressured vessels with care and care must be taken to ensure that all boiler mountings and safety devices are functioning prior to start up.

An essential condition on start-up is the water level and its associated alarms must be checked.

Mechanical or electrical failures can cause a faulty sensor or relay response to the alarms not being activated when water levels are low.

Common practise, or SOP for boilers is to ensure by all means that, the water level is sufficient at all times prior to firing. (Flanagan, 1990)

AGI found that for this case study, no water was present as displayed in the gauge glass and the boiler was still fired.

Possible Failure

Failure due to Poor Contact of Float Switch – Proximate Cause

Cause

Cochran Boilers have a vertical reed float switch. Reed switches open or close an electrical circuit, based on certain external conditions; in a float switch, this means liquid levels.

AGI found there was poor contact of the float switch was evident.

The above case study proves just how important it is to ensure that all safety trips and automations of a machinery are in proper working order at all times. Testing is a vital part of procedure prior to any firing, along with carrying out regular periodic maintenance. A failure investigation company will bring knowledge and expertise to your equipment, including the specifics of your processes. They also provide objectivity during these challenging times by providing clarity around the most cost-effective means of resolving issues you are facing, ensuring you get you back to being fully operational in the quickest and most cost-effective fashion possible.