On 24 December 2019, one of the printing machines in a local signage manufacturing company reportedly malfunctioned during the start up. The malfunction was discovered by the director of the company when the machine was being started up for routine cleaning. The Ultraviolet printing machine (UVPM) failed to function when it was switched on, however, the power supply indicator light illuminated showed that there was power in the circuit.

The Director then contacted the maintenance company and upon their advice, attempted to restart the machine a few times by operating the disconnector switch. Nevertheless, the problem persisted and the maintenance company was instructed to conduct a complete inspection. After troubleshooting the UVPM, the vendors concluded that the printer’s motherboard and printhead chipsets were damaged, allegedly due to a lightning strike.

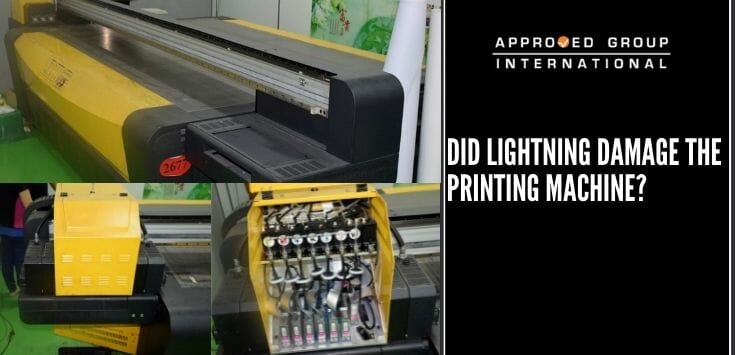

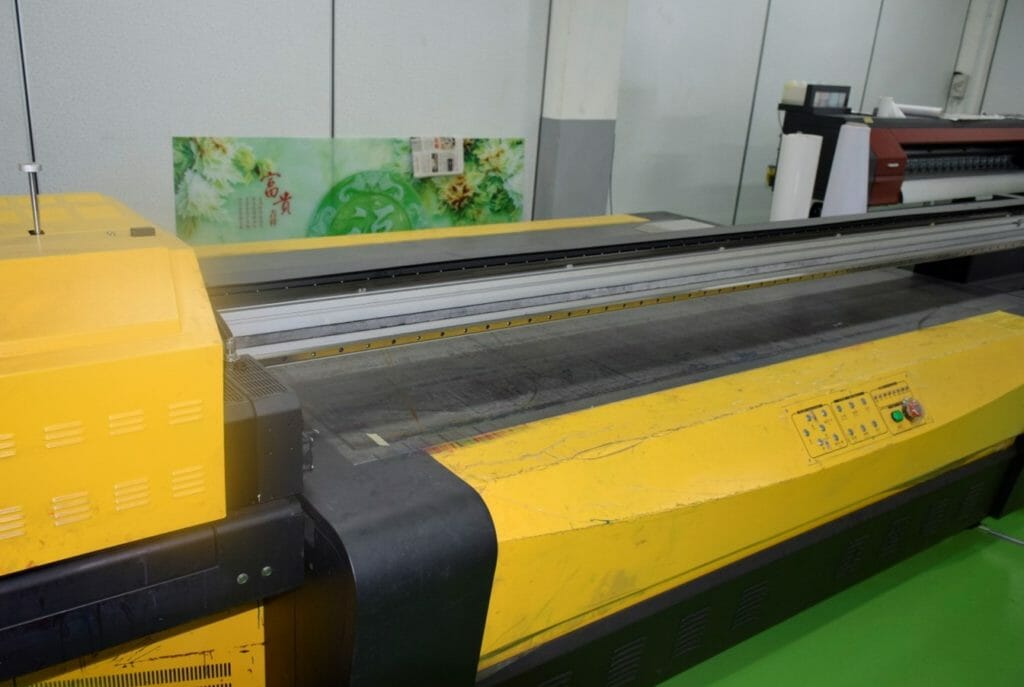

An overall view of the affected UV Printing Machine (UVPM). There was no physical damage observed on any section of the exterior casing of the print head, control panel or the flat bed of UVPM.

AGI was appointed to investigate the cause of damage and assess its extent to the UVPM. On 13 May 2020, AGI’s team met with the directors of the signage company and held a discussion to understand the circumstances of the incident. Following this, the machine’s components were inspected and the alleged affected parts were identified. A routine check of the electrical circuit was carried out and the machine was switched ‘on’ to verify the condition of the disconnector switch and Miniature Circuit Breakers (MCB).

Other components of the UVPM such as the power supply boards and cables were tested followed by a thorough inspection of the building and room’s overall condition. The team also recorded statements from the director who had handled the machine prior to the malfunction and copies of the UVPM’s instruction manual was obtained.

The UVPM which was installed in 2015, was maintained by the director from 2017. The machine was in use whenever there was printing work. Routine cleaning procedures were scheduled 3 times a week to avoid the ink from drying which could affect the print heads. The machine was reported to be functioning normally three days before the malfunction and no issues were reported during its cleaning procedures. Upon completion of the cleaning procedure, the machine was turned off using the disconnector switch.

To better understand the malfunction, AGI examined the damaged motherboard of the UVPM closely. All of the machine’s operations are controlled by the motherboard inside the control cabinet of the printer. Connected to various drives, limit switches, computer and UV lamps, the motherboard controls all the machine operations according to the input given through the computer or the control panel.

However, when the vendors carried out their inspection, the motherboard was reportedly dismantled and brought back to their office for inspection. The printer’s headboard and printhead chipset were also reportedly affected, however, the drying of the print head was suggested to be due to the non-operation/cleaning of the heads.

Overall view of the print head. There was no physical damage observed within the print head. However, a discussion with the vendor revealed that the print head became dry due to prolonged non-operation of the printer machine and this affected the printer head units.

AGI’s team tested the motherboard by connecting it to the connectors and its labelling on the connectors and pins to indicate the board’s originally installed position within the machine itself.

An overall examination of the building and printer room did not indicate any physical damage due to a direct lightning strike. The printer machine and computer installed beside UVPM was found to be unaffected and working as per normal.

There was no physical damage indicating a direct lightning strike observed on the building structure. A lightning arrester was installed on the top of the building (red arrow).

There was no damage reported to any other installation within the premises except the UV Printing Machine (UVPM). Both printers were connected to the electrical supply separately. There was no physical damage observed on the printing room structure.

The computer connected to UVPM was unaffected.

Other components inspected were the external electrical circuit, disconnector switch, and protective MCB which were all found to be fully functional. The power supply card did not indicate any component failure. A functionality testing was conducted with normal output voltages being measured at all the terminals.

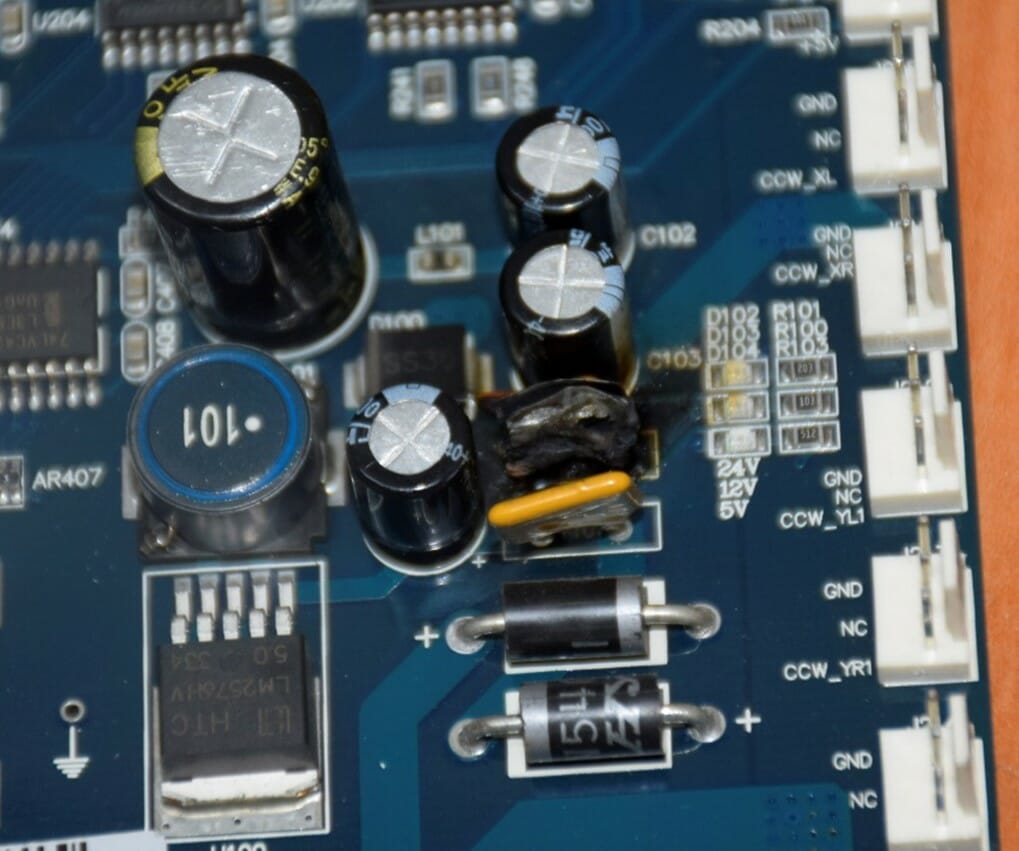

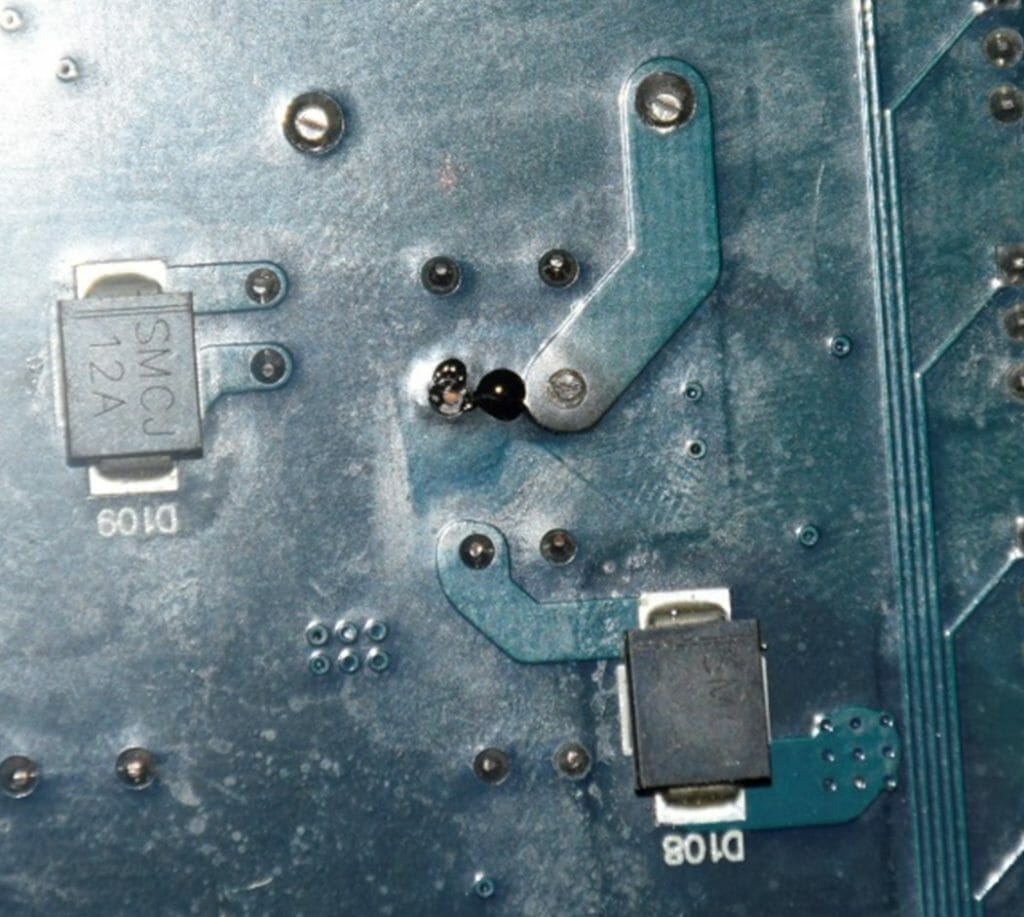

The printhead chipsets were reportedly affected during the prolonged non-operation period leading to drying of ink, however, the maintenance company clarified that the damage was not directly related to the malfunction. The machine could not be operated due to the faulted motherboard and this affected the printhead boards. The motherboard was found to have one burnt polyfuse on it displaying charred material.

A detailed inspection of the motherboard was conducted and one polyfuse on the board was found to be burnt, the component was completely charred and the components near the fuse displayed soot deposits.

One of the diodes and one Metal Oxide Semiconductor Field Effect Transistor (MOSFET) in the internal component had also short circuited, suggesting that the machine had malfunctioned due to the faulty motherboard.

The overall examination of the building showed no signs of a lightning strike whereas the metallic control cabinet which housed the motherboard also had no visible signs of damage ruling out the possibility of a direct lightning strike. Possible routes of exposure were analysed. Further inspection ruled out the possibilities of a damage to the motherboard due to a power surge from incoming power supplies.

Overall view of the unaffected printer machine. The disconnector switch (red arrow) for the UVPM power circuit was mounted on the wall beside the unaffected printer.

As the internal circuit of the components were found to have a common grounding with the power supply, it is not possible for a ground potential rise to induce a power surge within the machine. A key point to note is that the weather report of the area proved there were no lightning strikes near the premises during this reported period. As such, a surge due to ground potential rise or induced emf in the circuit as a result of nearby lightning strike is ruled out.

The AGI team concluded that the malfunction could not have been a result of a lightning strike based on the nature of damage within the motherboard, analysis of the extent of damage and verification of all possible routes of exposure. The damage was due to internal component failure due to continuous usage.

In dealing with complex machinery such as this, the cause of damage could be due to any number of possibilities. However, in order to get to the root of the problem, its best to call in the forensic experts to assess and examine the machine and situation. Ready to receive professional assistance from a team of forensic experts? Get in touch with us today at [email protected]!