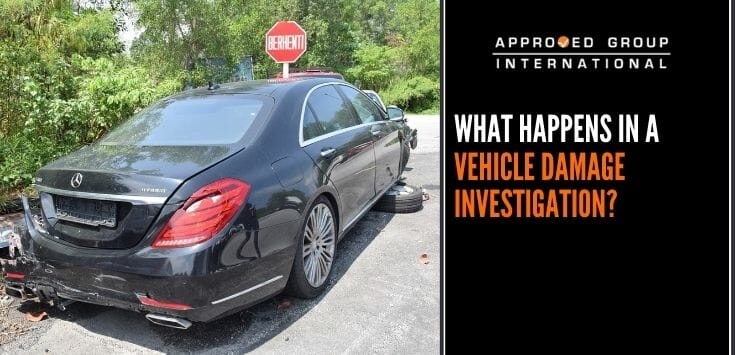

Research has demonstrated that road accidents occur more frequently during festive seasons, leading to an increase in claims around this period. Vehicle damage repairs can cost a fortune and one of the key parts of the rectification process is the insurance claim. However, a Vehicle Damage Investigation (VDI) is often done to determine the consistency of the vehicle’s damage with the incident circumstances described by the insured.

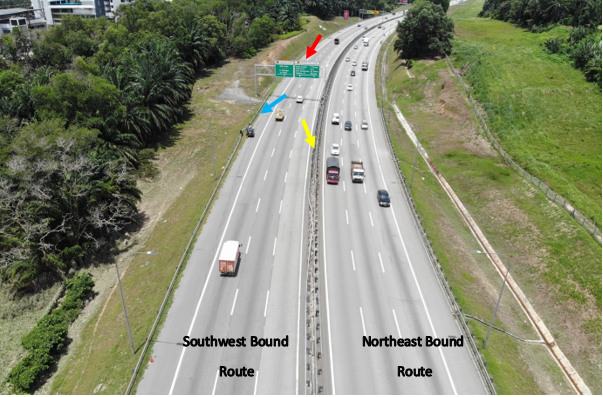

Recently, Approved Group International (AGI) was appointed to conduct a VDI following an incident which occurred on the New Klang Expressway (NKVE). The VDI included interviewing the driver, an on-site investigation, evidence documentation, and accident reconstruction simulation.

The driver of the vehicle recounted the incident to our team. He explained that he was driving in the middle lane on the way back to Damansara, when the Mercedes he was driving, passed through a puddle of water. This caused him to suddenly lose control of the Mercedes which spun and collided with the middle guardrail. The collision caused his Mercedes to spin several more times before coming to a halt in between the right and middle land. The driver noted that it was raining during the incident and his travelling speed on the highway was around 110km/h.

After alighting from the Mercedes, he started to look for his mobile phone but did not locate it, as ‘call men’ began arriving at the scene. Around 10-20 minutes later, another vehicle travelling on the same route collided with the debris from his Mercedes. Coincidentally, the driver of that vehicle was a friend whom he hitched a ride with to the police station to report the incident.

AGI gathered information on the condition of the Mercedes, injuries sustained by the driver, his familiarity with the road used and details of the vehicle as the driver was not the owner of the Mercedes.

Next, our team visited the site of the incident to conduct the scene examination and documentation which included still and aerial photographs, sketches with measurements and a 3D map generated using a quadcopter. The Mercedes was also inspected, photographed and soil samples were taken from its detached engine assembly. The findings of the inspections are as follows.

The Mercedes sustained physical damage mostly at the engine compartment, front left passenger door and rear left section. The right side of the Mercedes and its roof had no significant damage. In the boot section, there was a fractured taillamp, the rear bumper cover had fractured and torn towards the middle and the exhaust tailpipe on the left had become dislodged. As such, the damage profile observed is consistent with a frictional motion impact with an object with double protruded facings on the upper region.

Examination of the front near side depicted a strip of guardrail was protruding out of the door causing the outer door panel to puncture and partially dislodge. The left rear-view mirror was damaged. The same guardrail had pierced through the firewall and emerged out at the engine compartment. Detailed inspection of the vehicle concluded that the extensive damage was also consistent with an impact with a wide blunt object.

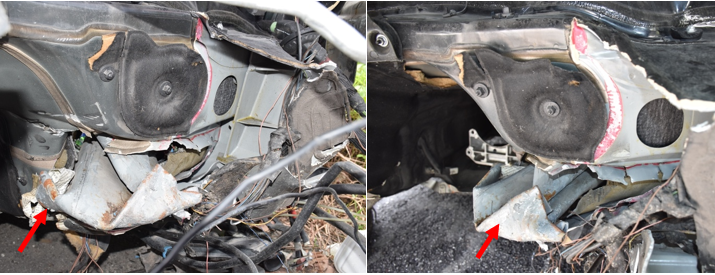

The engine compartment of the Mercedes was found to have sustained impact damage causing the heavier compartments within to be pushed to the left with the fittings detached. The Mercedes’ bonnet was deformed and crumpled towards the left. The bonnet exhibited transverse abrasion marks on its front edge whereas the right fender was fractured and torn. Inside, several components such as the engine, exhaust manifold, transmission, front axle, engine cooling, air conditioning, front bumper cover and grille were dislodged.

The passenger compartment sustained no other major damage besides the front passenger seat caused by the guardrail strip. The driver’s airbag and both curtain airbags had deployed and the steering wheel had rotated about 135° clockwise.

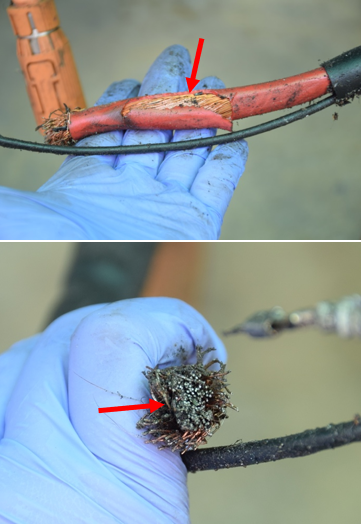

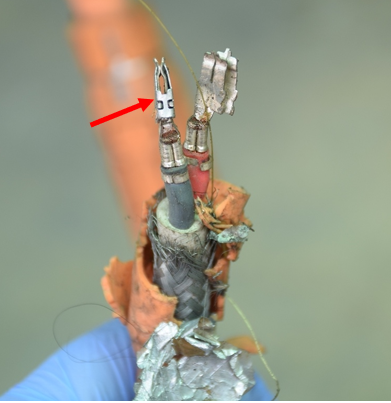

Upon inspection, the transmission, engine and front axle assemblies had dislodged from the Mercedes and was stored separately. The propeller shaft was still connected to the transmission case which was physically intact but displaying minimal chip-offs. The main wiring harness’s terminal end had abraded but the hybrid wiring harness’s terminal ends remained physically intact.

There was no physical damage observed on the lower end of the engine block, but residues of soil and plant were found stuck on the components on the left of the engine block indicating that the top left side of the engine block sustained impact damage causing it to land on soiled ground with vegetation. Findings also showed that both front wheels had sustained a frontal impact damage.

The next issue was comparing the damage profile to the sequence of events relayed by the driver to determine the consistency of the damage. The team’s analysis concluded that the damage profile did indeed match the incident circumstances as provided by the driver.

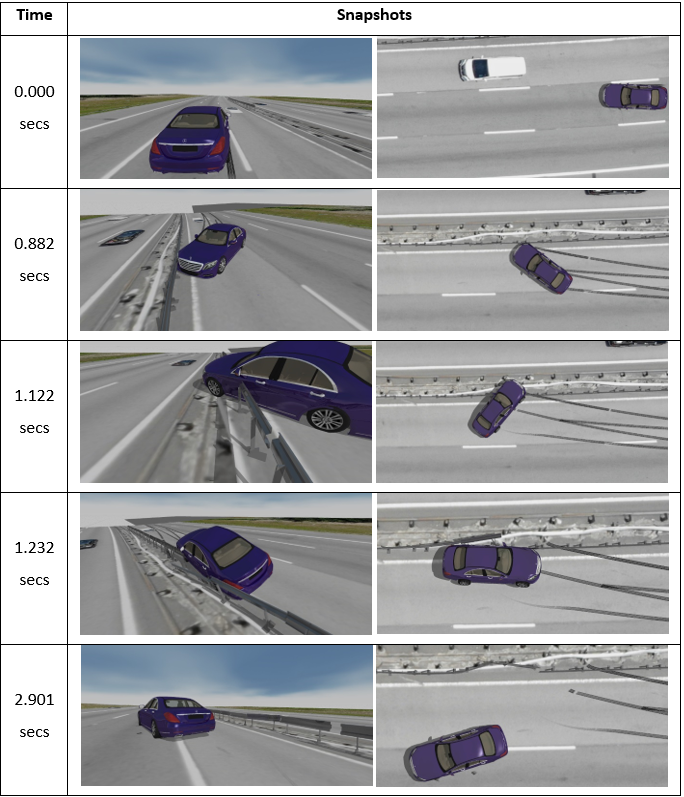

In situations like this, having a first-person perspective to the incident always assists. Using a validated Crash software, our team carried out a computer simulation to verify the damage consistency to the statement provided. The simulation uses a physics module that calculates and predicts the movement and/or post-collision dynamics of the subject vehicle. Widely used by a number of industries, including some universities in Europe and North America, this software is thoroughly validated for professional use.

Below are the snapshots of the simulation as per the driver’s statement.

Table 1: Snapshots of the First Scenario

Comparing the expected damage to the observed ones, the results obtained in the simulation matches that of the actual circumstances described by the driver.

The last part of the investigation was a soil analysis done on the residues of soil and plant collected from the Mercedes and site of incident. The residues’ morphology was examined macroscopically and microscopically. The findings concluded that both residues collected were similar in their morphology.

The process of conducting a vehicle damage investigation needs to be done meticulously as it is vital to cover all bases of the incident. Our team of professionals are highly experienced in this field. Armed with the skills, software and expertise, we produce credible and timely forensic investigation reports, prepared in accordance with the technical standard ASTM International E620 – 18 – Standard Practice for Reporting Opinions of Technical Experts. Need our assistance in similar matters? Contact us now!