A Mitsubishi generator was reported to have failed within the premises of power generation station at South Ternate, North Maluku, Indonesia. The incident was discovered when the alarm system of the generator activated. The Air Circuit Breaker (ACB) for the generator was later found to have tripped, and the generator had stopped working. Subsequent examination by the maintenance personnel revealed that there were remains of metal residue in the oil sump of the engine, and the crankshaft was fractured.

Approved Forensics Sdn Bhd (AFSB) was appointed by the insurers to investigate the cause of the failure to the generator. The investigation was conducted through a site visit, data gathering and forensic study. During the visit, the investigation team conducted an interview with the maintenance personnel to gather information on the details of the incident.

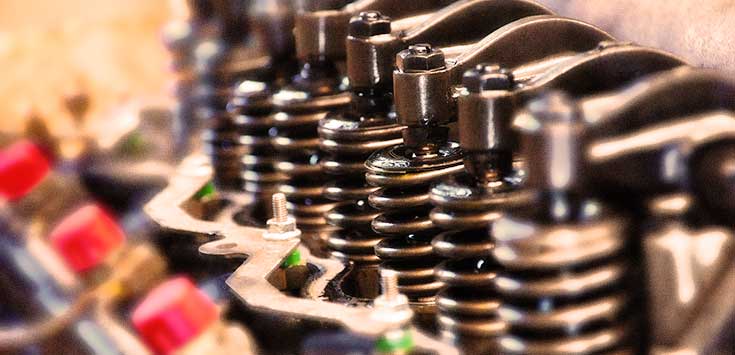

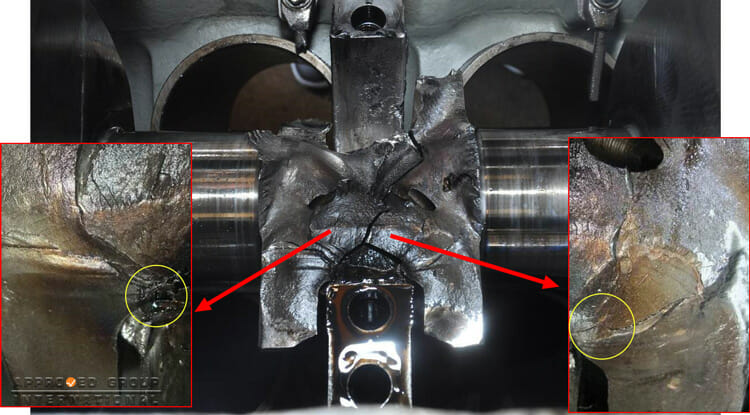

The investigation team also conducted a thorough on-site investigation and examination of the affected engine components. During the course of the investigation and examination, the team performed damage analysis, metallurgical analysis and scientific interpretation of the damaged engine components to determine the area of origin and the cause of failure. The team also procured the maintenance records and operation data of the affected engine for further study. Following the Team’s on-site investigation and examination, potential causes of failure were considered based on the physical evidence and information available to the investigation team during the investigation. The investigation team had eliminated several of the potential causes of failure, which includes external factor, oil contamination, overheating, human involvement, operator error and inadequate maintenance. The investigation team found that there are no suspicious circumstances surrounding the incident. The detailed on-site examination revealed two (2) macroscopic fatigue features on the fracture surface of one of the main journals and the adjacent crank webs, which are the ratchet marks and progression marks. These features indicate that the cracks had initiated at or near to the main journal fillets and both corner regions between the main journal and the adjacent crank webs.

Based on the investigation and on-site examination, the investigation team concluded that the failure was caused by a material fatigue.