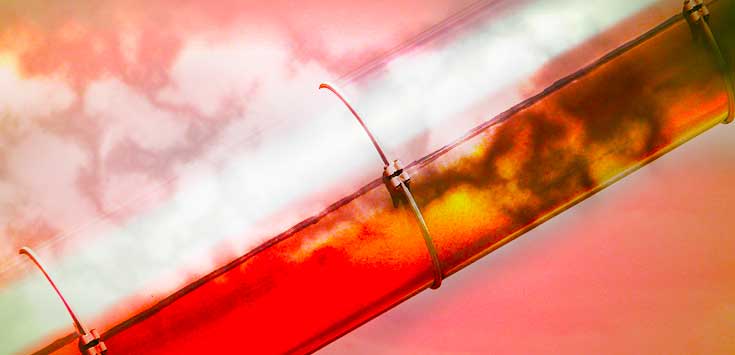

At approximately 1300 hours on Saturday, 14 December 2013, a loud bang resembling an explosion was heard at the exhaust ducting of Gas Turbine Generator (GT) 1 after eleven (11) attempts of ignition during the maintenance period. Further external inspection conducted on GT-1 revealed that a number of bypass ducting bellows had ruptured and deformation was observed at the economiser casing. This report presents the findings and results of the investigation and examination of the origin and possible cause of the explosion. The investigation was conducted through site visits, data-gathering and forensic study. During the visits, the investigation team conducted a thorough on-site investigation and examination of the scene. During the course of the investigation and examination, the Team performed damage analysis and scientific interpretation of the scene to determine the possible area of origin, and potential cause of explosion.

Based on the Team’s overall inspection and damage analysis of GT-1 and the surrounding area, the flame front from the fire which had initiated within the combustion chamber during the gas ignition sequence had propagated through the interconnected bypass ducting which contained accumulated natural gas. An explosion ensued as the flames acted as the ignition source to the pre-mixed fuel air cloud (fuel load) within the bypass ducting when the concentration ratio of natural gas and oxygen reached the lower explosive limit.

Based on the evidence, damage analysis and from the process of elimination of all other possible causes, the Team found that the explosion had commenced as the result of defective gas control valves and insufficient purging time.

The Team recommend that the main and pilot control valves be replaced. It is also essential to increase the purging time from 40 seconds to the recommended 350 seconds.